Molino-Projekt – Führerhaus, Tender und mehr

Guten Morgen, nach einer kleinen Pause geht es hier nun mit dem Bau meiner Molino-Shay weiter.

Mein Papa hat für mich auf unserer cnc-Fräse die Teile für das Führerhaus gefräst und Füllstücke für die Pufferbohle.

Die Führerhauswände bestehen aus 2 Lagen. Einen Innenwand aus 0.5mm Messing und einer Aussenwand aus 0.3mm Messing. Die Außenschicht wurde auf der Innenseite dünn verzinnt, die Teile dann mit Metallklammern zusammen geklemmt und mit der Lötlampe verlötet. So entstehen die zurück gesetzten Fensterrahmen und die typischen Kassetten in der Seitenwand.

Auch sonst wurden am Führerhaus alle Verbindungen gelötet, diesmal aber mit dem Lötkolben. Flußmittel und feines Elektroniklot gehen hier sehr gut. Das Führerhaus wurde zudem auf der Bodenplatte aus Messing aufgelötet und gibt somit der Verbindung zwischen Kessel und Messinganbau zusätzlichen Halt. Unterdessen habe ich auch die Füllstücke aus 1mm Polystyrol in die Pufferbohlen eingeklebt.

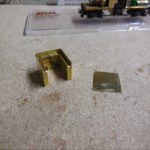

Der Tender entstand wieder konventionell aus Messing. Ein Stück 0.5mm Blech wurde zugeschnitten und in Form gebogen. Auf die Innenseiten der Seitenwände habe ich Abschnitte von 2x10mm Flachprofil aufgelötet um das Gewicht zu erhöhen und gleichzeitig eine Auflage für den Deckel aus 0.5mm Blech zu haben. Der Deckel wurde aufgeklebt, ebenso der Tender auf dem Rahmen.

Neben meiner 13ton Sugiyama Shay wirkt die neue Molino Shay richtig winzig. Ich war selbst überrascht wie klein die Lok wird Vergleiche mit H0-Figuren und Vorbildfotos zeigen aber, daß die Größe der Molino 10ton Shay sehr gut getroffen ist.

Somit wäre das neue Gehäuse im Rohbau fertig und es kann an die Details gehen wie Nietbänder, Rohrleitungen, Handgriffe…..