[CFF] Krauss-Lok Teil 2

Weiter geht es mit dem 2. Teil der Krauss-Lok. Wie bereits letzte Woche berichtet stolperte das Projekt über das Problem, wie ich die Akkus tauschen kann. Hierbei haben mir zwei Lösungen weiter geholfen. Zunächst wird das gesamte Gehäuse mit Kessel, Wasserkästen und Führerhaus abnehmbar vom Fahrwerk aufgebaut. Somit kann der Akku im Kessel platziert werden und ist weiterhin zugänglich. Die Elektronik konnte ich komplett im Bereich unter dem Führerhaus verstecken (etwas eng, aber es geht). Die zweite Neuerung ist, daß ich diesmal den Lipo-Wächter fest in der Lok verbaut habe und dieser ebenfalls über den Einschalter geschaltet wird.

Noch bevor ich aber die Elektronik-Lösung gefunden habe, hatte ich damit begonnen weitere Teile für den Kessel anzufertigen. Zunächst entstand die „Krone“ für den Dampfdom. Alle Teile wurden aus Messing angefertigt. Der neue Sanddom nach Bauart „Krauss“ wurde aus einem massiven Stahl-Block gefräst. Einige Bauteile wurden beibehalten, andere neu angefertigt. Zu letzt wurde noch das Stehkessel-Element an das neue Führerhaus angepaßt und dann fest mit dem Langkessel verbunden.

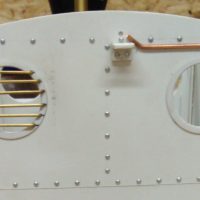

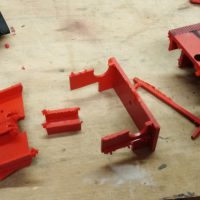

Ebenfalls für lange Zeit ungeklärt war das Baumaterial für das Führerhaus. Letztlich habe ich mich für ABS-Platten entschieden und habe diese Entscheidung nicht einmal bereut. Auch wenn es auf den ersten Blick nach cnc-Fräse aussieht – alle Teile wurden konventionell auf den üblichen Werkstattmaschinen angefertigt. Teile die doppelt oder mehrfach benötigt werden habe ich wenn möglich als Paket gleichzeitig bearbeite. Somit sind die annähernd Deckungsgleich. Die Niete aus Aluminium wurden von Hand in vorgebohrte Löcher gesetzt. Alle gebogenen Teile wurden mit einer Matrize aus Blech und unter Einsatz des Heißluftföns geformt. Dabei sollte man auf beiden Seiten ein Aufmaß berücksichtigen, da das ABS quer zur Biegekante schrumpfen kann. So ist es mir bei den Wasserkästen ergangen, aber ich konnte es mit eingesetzten Kunststoffstücken wieder richten.

Im nächsten Bericht kommt dann noch etwas Farbe ins Spiel und ich möchte noch mal im Detail auf Elektronik und das abnehmbare Gehäuse eingehen.

[CFF] Die Anfänge meiner neuen Krauss-Lok

Bereits vor einem Jahr hatte ich mir eine gebrauchte HF110c (Frank S.) von LGB besorgt, aus der ich die Waldbahn-Lok von Abreschviller nachbauen wollte. Um mich nicht zu verzetteln wurde das Projekt dann aber doch noch rechtzeitig abgebrochen. Doch was sollte ich nun mit der Lok machen? Da ich schon länger an einer Akku-Dampflok als Verstärkung für meine Resita-Lok interessiert war, ging es an die Arbeit die vorhandene HF110c für den Einsatz in Rumänien zu überarbeiten. Von einer Baureihe U von LGB besorgte ich mir einen Satz Zylinder und Steuerungsgestänge, was ich von der HF110c nicht verwenden konnte wurde im Gegenzug verkauft (Tender, Führerhaus, Kleinkram).

Zunächst wurden an den Kurbeln der Achsen die Gegengewichte entfernt. Dazu nutzte ich ein passendes Stück Rundstahl als Schleiflehre. Der Rahmen machte hier einiges mehr Arbeit. Die Zylinder wurden gegen jene der U-Lok getauscht um den typischen „Krauss-Look“ zu erhalten. Als Anregung nahm ich die Vorbildlok 763-247, die unter anderem in Oituz und Commandau stationiert war. Diese Lok besitzt zusätzlich ein 2-achsiges Vorlaufdrehgestell (2’C), welches ich bei meiner Lok jedoch unterschlagen habe. Das Anpassen der Steuerungsträger und der Umbau des vorderen Rahmenteils erforderte ein wenig Tüftelei. Die Pufferbohlen wurden komplett neu aufgebaut und mit meinen CFF-Kupplungen bestückt. Für eine gefällige Proportion wurde der Rahmen am Heck ein klein wenig verlängert und der Rahmendeckel abgeschnitten. Der neue Führerhausboden wurde auf dem bisherigen aufgesetzt, so dass das Führerhaus ebenfalls etwas höher kommt.

Guter Dinge ging es danach mit dem Umbau des HF110c-Kessels weiter. Der Sanddom wurde entfernt und sollte ersetzt werden. Den neuen Schornstein nebst Kobel hatte ich bereits auf der Drehbank aus Stahl angefertigt. Beim ausbohren des alten Schornsteins war mir zwar der Bohrer abgerutscht und hatte ein fieses Loch in die Rauchkammer gerissen, doch das kann man mit etwas Spachtelmasse wieder zu bekommen, so wie auch die anderen Löcher von Anbauteilen.

Doch dann kam das Lokbauprojekt für gut ein halbes Jahr zum Stillstand, da ich ein ganz wichtiges Problem vergessen hatte: WO bringe ich den Akku unter und WIE kann ich ihn zum Laden herausnehmen. Ich verwende 4 Lipo-Akkus für meine derzeit 8 Gartenbahn-Loks, da ich nie alle Fahrzeuge gleichzeitig einsetze und so die Akkus regelmäßiger genutzt und geladen werden. Daher ist es erforderlich die Akkus aus den Loks herausnehmen zu können. Bei den bisherigen Modellen gab es immer einen Tender, den man abnehmen oder öffnen konnte, doch bei der neuen Krauss-Lok nicht.

Eine Lösung fand sich erst im letzten Spätjahr, doch davon erzähle ich euch im nächsten Beitrag.

Neues Jahr, neue Projekte…

Hallo liebe Waldbahnfreunde und Willkommen zurück hier in meinem Blog.

Ich hoffe ihr hattet einen guten Start ins Jahr und ich wünsche euch natürlich noch alles Gute.

Das neue Jahr bringt neben einiger neuer Projekte und Ideen auch ein paar Änderungen mit sich. So möchte ich von den bisher wöchentlichen Beiträgen auf einen monatlichen Rhythmus umstellen, oder je nach Projektfortschritt, um so die Zeit zwischen Arbeit, Hobby und Familie besser aufteilen zu können, da ich sehr viel Zeit für das regelmäßige Posten hier im Blog aufgebracht habe.

Bereits im letzten Jahr habe ich begonnen meine Sammlung zu bereinigen, Kompromiss-Modelle und überzählige Fahrzeuge wurden verkauft und so Budget für das neue Jahr generiert.

Und ebenfalls im letzten Jahr ist diese Krauss-Waldbahnlok für meine rumänische Waldbahn aus Basis von LGB-Teilen entstanden. Eine genauere Vorstellung und ein paar Infos zum Bau werde ich in den nächsten Tagen einstellen.

Grüße, Gerd