[CFF] Die Anfänge meiner neuen Krauss-Lok

Bereits vor einem Jahr hatte ich mir eine gebrauchte HF110c (Frank S.) von LGB besorgt, aus der ich die Waldbahn-Lok von Abreschviller nachbauen wollte. Um mich nicht zu verzetteln wurde das Projekt dann aber doch noch rechtzeitig abgebrochen. Doch was sollte ich nun mit der Lok machen? Da ich schon länger an einer Akku-Dampflok als Verstärkung für meine Resita-Lok interessiert war, ging es an die Arbeit die vorhandene HF110c für den Einsatz in Rumänien zu überarbeiten. Von einer Baureihe U von LGB besorgte ich mir einen Satz Zylinder und Steuerungsgestänge, was ich von der HF110c nicht verwenden konnte wurde im Gegenzug verkauft (Tender, Führerhaus, Kleinkram).

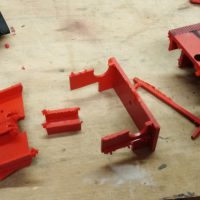

Zunächst wurden an den Kurbeln der Achsen die Gegengewichte entfernt. Dazu nutzte ich ein passendes Stück Rundstahl als Schleiflehre. Der Rahmen machte hier einiges mehr Arbeit. Die Zylinder wurden gegen jene der U-Lok getauscht um den typischen „Krauss-Look“ zu erhalten. Als Anregung nahm ich die Vorbildlok 763-247, die unter anderem in Oituz und Commandau stationiert war. Diese Lok besitzt zusätzlich ein 2-achsiges Vorlaufdrehgestell (2’C), welches ich bei meiner Lok jedoch unterschlagen habe. Das Anpassen der Steuerungsträger und der Umbau des vorderen Rahmenteils erforderte ein wenig Tüftelei. Die Pufferbohlen wurden komplett neu aufgebaut und mit meinen CFF-Kupplungen bestückt. Für eine gefällige Proportion wurde der Rahmen am Heck ein klein wenig verlängert und der Rahmendeckel abgeschnitten. Der neue Führerhausboden wurde auf dem bisherigen aufgesetzt, so dass das Führerhaus ebenfalls etwas höher kommt.

Guter Dinge ging es danach mit dem Umbau des HF110c-Kessels weiter. Der Sanddom wurde entfernt und sollte ersetzt werden. Den neuen Schornstein nebst Kobel hatte ich bereits auf der Drehbank aus Stahl angefertigt. Beim ausbohren des alten Schornsteins war mir zwar der Bohrer abgerutscht und hatte ein fieses Loch in die Rauchkammer gerissen, doch das kann man mit etwas Spachtelmasse wieder zu bekommen, so wie auch die anderen Löcher von Anbauteilen.

Doch dann kam das Lokbauprojekt für gut ein halbes Jahr zum Stillstand, da ich ein ganz wichtiges Problem vergessen hatte: WO bringe ich den Akku unter und WIE kann ich ihn zum Laden herausnehmen. Ich verwende 4 Lipo-Akkus für meine derzeit 8 Gartenbahn-Loks, da ich nie alle Fahrzeuge gleichzeitig einsetze und so die Akkus regelmäßiger genutzt und geladen werden. Daher ist es erforderlich die Akkus aus den Loks herausnehmen zu können. Bei den bisherigen Modellen gab es immer einen Tender, den man abnehmen oder öffnen konnte, doch bei der neuen Krauss-Lok nicht.

Eine Lösung fand sich erst im letzten Spätjahr, doch davon erzähle ich euch im nächsten Beitrag.

Hallo Gerd,

schöner Auftakt, ich bin sehr gespannt auf das weitere Erscheinungsbild der Lok!

Wenn ich fragen darf: Warum verwendest Du LiPo-Akkus und nicht LiIon-Akkus? Ich kann mir kaum vorstellen, dass Du wesentlich mehr als 5 Ampere abfragen musst und im Gegenzug sind LiPos ziemlich teuer und recht kurzlebig im Vergleich. Oder bist Du auf die schmalen Bauformen angewiesen?

Und dann noch eine zweite Frage: Warum ein stählerner Schornstein? Mehr Gewicht für die Traktion? Oder einfach nur Spaß am Drehen? ;-)

Beste Grüße,

Frédéric

Auf die Akkulösung bin ich mehr als neugierig – bis jetzt tolle Abeit!

Hallo Gerd,

das ist eine sehr schöne Bastelei die du hier zeigst.

Bin gespannt wie es weiter geht.

Grüße Hagen

Hallo Gerd!

Eine interessante Hintergrundgeschichte. Bin gespannt, wie es weiter ging.

Wie schon einmal erwähnt ist Dir da eine sehr schöne, markante Waldbahnmaschine gelungen.

Viele Grüße, Tobias