Weihnachtszeit -> Familienzeit

Hallo Waldbahnfreunde,

wo ist nur das Jahr geblieben… ?

Kommenden Sonntag beginnt schon wieder die Adventszeit und in den letzten Jahren lief meine Modellbahnwerkstatt da erst so richtig auf Hochtouren. Für die damalige Teilnahme am Echtdampfhallentreffen gab es immer viel vorzubereiten und so manches Projekt wurde kurzfristig noch zwischen rein geschoben wie z.b. der Bau einer kompletten Drehscheibe in Spur 5″.

Fast alle diese Projekte wären nicht möglich gewesen, würden meine Frau und Familie nicht großzügig Freiräume dafür geben, wenn auch nicht selten mit heftigem Kopfschütteln.

Daher finde ich es mehr als nötig mich dafür zu bedanken, in dem ich mir die kommenden Wochen „Modellbahnfrei“ gebe. Ich möchte die Zeit dieses Jahr ganz der Familie widmen, die neben Bastelprojekten, Ausstellungen und Fahrtagen manchmal doch auch sehr kurz gekommen ist.

Daher wünsche euch schon vorab eine besinnliche Adventszeit, sowie frohe Festtage. Wir sehen/lesen und im neuen Jahr wieder.

Liebe Grüße, euer Waldbahner aka Gerd.

[CFF] Begleitwagen Bauart „Moldovita“ (Teil 2)

Tja, und da ist der Wagen auch schon fertig…

Wie schon im ersten Teil gibt es leider keine Detailbilder vom Bau. Bei Fragen zu Details helfe ich euch aber sehr gerne weiter.

Nach dem montieren der Profile wurden alle Messingteile per Pinsel schwarz lackiert. Die Fensterrahmen wurden auf die Kunststoffscheiben aufgeklebt und dann die fertigen Fenster eingesetzt. Weitere Details wurden aus Kunststoff oder Metallteilen ergänzt. Besonders spannend war dann nochmal das Dach, welches ich aus 3 vorgebogenen Blechstücken zusammen gesetzt habe. Im Inneren sorgen zwei Sperrholzbögen für die nötige Stabilität. Zum Bestaunen der Inneneinrichtung wurde das Dach abnehmbar belassen.

Und auch dieser Wagen bekam sein finales Finish aus der Airbrush. Die Transformation ist immer wieder erstaunlich. Das dritte Bild zeigt auch einen Blick auf die Einrichtung. Die Tür ist mit echten Scharnieren beweglich aufgehängt.

Zum Abschluß noch ein paar Bilder vom Einsatz im Garten.

Grüße, Gerd

[CFF] Begleitwagen Bauart „Moldovita“ (Teil 1)

Nach kurzer Pause geht’s nun mit dem nächsten Wagen weiter, der ebenfalls von der Waldbahn Moldovita inspiriert ist. Dort wurde oft ein kleiner 2-achsiger Pack/-Begleitwagen in die Züge eingereiht. Dieser knuffige Wagen hatte es mir allein schon wegen der Form immer mal wieder angetan.

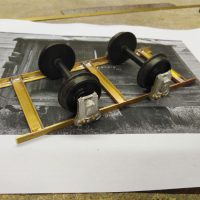

Aus der großen Bastelkiste kramte ich ein Paar 26er Metall-Radsätze von Modellbau Heyn sowie ein Satz Achslager von OZARK. Mit ein paar Messingprofilen war das tragende Fahrwerk schnell aufgebaut. Doch dann wurde es schnell kompliziert…

So kompliziert sogar, daß ich völlig vergessen habe Bilder zu machen. Der Aufbau hat durch die eingezogenen Seitenwände eine achteckige Form und ist im Original ein Profil-Gerippe mit Brettern. Für die Umsetzung in 1:19 schon eine gewisse Herausforderung, möchte man den Wagen auch Innen schön bauen. Letztlich habe ich mir für eine Sandwich-Bauweise entschieden. Die Bodenplatte und Seitenwände bestehen aus 2mm Sperrholz, welche mit Messingwinkeln von innen verschraubt sind. Anschließend wurden aus dünnen Leisten die Bretter aufgeklebt. Der untere Rahmen besteht wieder aus verschiedenen Messingprofilen.

Die Profile auf dem Wagenkasten habe ich mir aus 0.3mm MS-Blech selber zugeschnitten und gebogen. Durch das Blech und den Holzkasten wurden Löcher gebohrt für 1mm Messing-Nägel. Diese wurden dann von innen eingesetzt, aussen verlötet und anschließend aussen wieder Plan gefeilt. Viel Arbeit, aber ich bin auf dem richtigen Weg glaube ich. Eine Seite ist geschafft, die andere hoffentlich auch bald.