[YPLC] Toma Shay – Teil 2

Hallo Freunde,

was soll ich sagen. Der Bau hat so viel Spaß gemacht, ich wollte gar nicht mehr aufhören. Und wieder mal war die Handykamera zwar immer mit in der Waldbahnwerkstatt, aber benutzt habe ich sie kaum. Ich hoffe ihr könnt euch dennoch an den folgenden Bildern erfreuen.

Am meisten beeindruckt hat mich der Kessel mit den kompletten Stehkessel-Armaturen. Diese habe ich farblich hervorgehoben. Es ist alles vorhanden vom Wasserstand über Manometer (inkl. Zeiger), Injektoren und Prüfhähnen. Das Schild auf der Rauchkammertür trägt sogar den Schriftzug der Lima Locomotive Co. ist jedoch kaum noch lesbar bei 0,35mm Schrifthöhe. Aber mit einem Drybrush konnte ich sie wenigstens andeutungsweise hervorheben.

Am Chassis habe ich vor dem Lackieren noch die Toma-Kupplungen für H0e-Bügel montiert und Haltegriffe über den Pufferbohlen aus 0.5mm Draht ergänzt.

Das Dach ist aus einem anderen Material als die restlichen 3D-Drucke und hat bereits eine sehr schöne Teerpapp-Oberfläche. Es wird mit den Stützen verschraubt, die dann an Kessel und Bodenplatte verschraubt werden. Generell kann die Lok dank kleiner Schrauben zerlegt werden, wenn man etwas reparieren oder umgestalten möchte.

Hier nun das fertige kleine Löklein nach Fertigstellung. Das Modell ist äußerst fein gelungen und gefällt mir in dieser offenen Ausführung ausgesprochen gut. Nun fehlen nur noch ein paar Kleinteile, Lokpersonal und Feuerholz. Eine erste Probefahrt auf der Waldbahn ist aber schon jetzt möglich :-)

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

[YPLC] Toma Shay – Teil 1

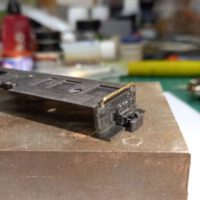

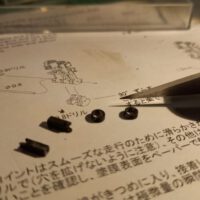

Und los geht’s mit dem Umbau des Chassis von statischem auf beweglichen Kardanantrieb. Viele der kleinen Teile sind noch an einer Art „Gussast“ und sollten auch an diesem verbleiben, bis sie bereit sind für den Einbau. Viele Löcher müssen von Hand noch auf das korrekte Maß gebohrt werden, um einen festen Sitz auf den Wellen zu erhalten.

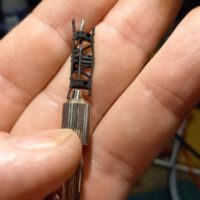

Meine Hand lässt deutlich erahnen wie klein die Teile sind. Der UV-Harz-Kunststoff ist im Übrigen recht stabil, aber dennoch spröde. Man muss also schon sehr sorgsam arbeiten. Außerdem sollte man die Anleitung (als PDF-Download nach Kauf verfügbar und sowohl Japanisch als auch Englisch verfasst) studieren. Die Vorgehensweise beim Bau ist sehr gut ausgeklügelt. Die überlangen Wellen z.B. werden mit einem Handkloben gehalten und so in die Passbohrungen geschoben. Mit bereits zuvor gekürzten Wellen wäre dies gar nicht möglich. Bilder hierzu habe ich weiter unten noch vorgestellt, wenn es an die Kardangelenke geht.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

Die Zapfen in den Kardangelenken sind auf 0.5mm Silberdraht. Diese sitzen press in den 0.5mm aufgebohrten Löchern des Ringes, während die Vierkantwellen des Längenausgleichs mit 0.6mm gebohrt werden. Wichtig ist sehr vorsichtig mit wenig Druck und von Hand zu bohren, damit die Löcher nicht zu groß werden (!).

Im letzten Schritt wurde dann noch die Dampfmaschine gebaut. Die Kurbelwelle ist vereinfacht ausgeführt mit einer durchgehenden Welle und ohne Treibstangen. Dies fällt bei dem kleinen Modell kaum auf, macht jedoch die Konstruktion sehr viel einfacher. Leider habe ich hiervon keine Bilder mehr gemacht, da der Zusammenbau solch großen Spaß bereitet hat.

Nach der Montage einiger letzten Zurüstteile am Rahmen für das Sprengwerk konnten alle Komponenten wieder montiert werden. Der Seitenantrieb wird von der vorderen Achse des hinteren Drehgestells angetrieben. Die anderen Kegelradgetriebe laufen als Dummy und die Zähne greifen nicht ein. Dadurch ergibt sich ein Störungsfreier Lauf. Das vordere Drehgestell wird von dem zentral liegenden Kardan angetrieben, der großteils vom Aschkasten verdeckt wird.

Please accept YouTube cookies to play this video. By accepting you will be accessing content from YouTube, a service provided by an external third party.

If you accept this notice, your choice will be saved and the page will refresh.

Im nächsten Beitrag zeige ich euch die Aufbauten und die vielen Details, besonders am Kessel.

[H0e] Toma Model Works Shay (3D-Druck)

Hallo Waldbahnfreunde,

nach dem kleinen Exkurs in Richtung Wales, geht’s nun wieder mit Waldbahnprojekten weiter. Den Anfang macht eine weitere Shay für 9mm Spurweite, die ich mich überwiegend aus Neugier gekauft habe.

Es handelt sich um den Bausatz von Toma Model Works aus Japan. Alle Teile sind in UV-Resin 3D gedruckt. Da ich mich nicht komplett an den Fahrwerksbau getraut habe, hatte ich mich für einen Bausatz mit vormontiertem Chassis entschieden. Dieser hat jedoch keinen beweglichen Kardan an der Seite. Diese Teile gibt es jedoch als Umbausatz separat. Da beides verfügbar war habe ich mich dann für diese Kombi entschieden.

Ein erster Blick in die Schachten löste zunächst etwas Schrecken aus. Das sind so winzige Teile, man kann sich kaum vorstellen, dass daraus ein funktionsfähiges Modell entstehen soll. Allerdings ist die Druckqualität und vor allem der Detail-Level überwältigend.

Das Fahrwerk läuft sehr langsam schon ab minimaler Spannung. Leider ist ein deutliches Surren zu vernehmen. Das kommt von dem kleinen Stirnrandgetriebe. Ein hohler Anlagenunterbau wie bei meinen H0e-Modulen verstärkt dieses Fahrgeräusch noch. Mal schauen, ob ich da etwas verbessern kann.

In den kommenden Beiträgen möchte ich euch vom Zusammenbau berichten.

Hm… was da wohl drin ist?

Mehr dazu demnächst hier, im Blog :-)